It was the early summer of 2013, and one day I decided to check out the Hoboken Makerbar, the local makerspace in Hoboken where I was living at the time. I met some folks there that were looking to enter a maker contest sponsored by Red Bull, where teams were given some LED light strips and a microcontroller driver board, and were challenged to build the coolest thing they could out of them. I suggested the most impressive thing I could think of doing, which was to build a persistence of vision display. We could turn our several feet of 1-dimensional LED strip into a giant 2-dimensional LED screen if we rotated it a high speed and could time when lights were turned on and off as the strip was rotated. Everyone quickly bought into the idea, but it was easier said than done - particularly since we only had 3 days before the contest deadline, and none of us had done anything like this before. But we decided to try anyway!

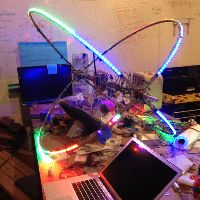

I basically spent every waking hour at the Makerbar for the next 3 days with a group of folks I had only just met, going home only to sleep. It was a real trial by fire and a great bonding experience for all of us. We grappled with questions of how to power the LED strips while they were spinning, how to detect position so we could know what to display on the strips at what time, and we experimented with how to physically support and rotate the LED strips while keeping a stable shape. At the end of the weekend we had done a lot of design, experimentation, learning, and actual physical construction, but in the end we had to bail on the POV idea because we couldn't get it all to work.

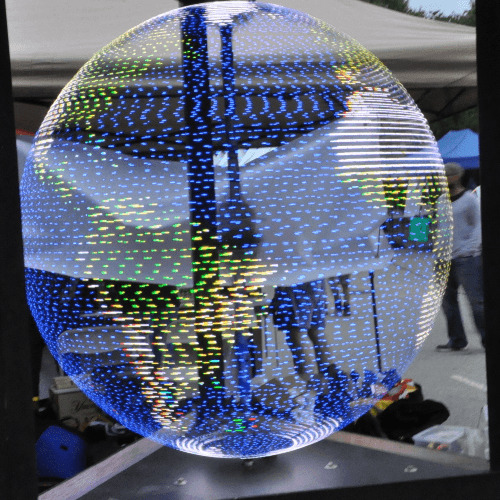

Still, we couldn't let the idea die. I had learned enough about microcontroller programming and about how to drive the LED strips over that weekend that I was sure it was possible, and after continually chipping away on the problem over the subsequent days I was finally able to get a stable POV image to show up on our makeshift globe. With this proof positive we decided to get even more ambitious with the project and set our sights on building it for the upcoming World Maker Faire in the fall.

We wanted the new globe to be even bigger and be capable of displaying video at 30 frames per second. In order to do this, we needed to be able to update the LED strips extremely fast: we would need to replace the image on the LED strip every time the LED strip rotated to a new horizontal position. The problem was that the WS2812 LED strips we were using are driven by a serial protocol that runs at a fixed internal clock speed, which meant that we could not update the LED strip faster than the fixed clock speed, and the longer the LED strip was, the more time it would take to update.

To get around this issue, we doubled the number of arms on our POV globe to four, so that the image on each arm would only need to be updated for one quarter of the horizontal positions during a rotation. We also subdivided each arm into 6 LED strips so that they would be shorter and could therefore be updated faster. In order to do this though, we had to be able to update 24 LED strips simultaneously.

Fortunately, we found a way to do this via the BeagleBone Black microcontroller and Trammel Hudson's LEDscape software. The BeagleBone Black has two programmable realtime units (PRUs), which are essentially separate programmable processors that can be run independently of the main CPU. Trammel's LEDscape software uses these PRUs to send display signals to WS2812 LED strips via memory-mapped I/O. By arranging the display buffer appropriately, it can send display signals to 24 GPIO pins simultaneously via a single direct memory access (DMA) instruction. This would get us the performance we needed.

Another issue was the physical build of the globe. The globe was four feet across, and needed a stable support structure. The LED arms were fashioned out of rolled aluminum, and the triangular superstructure was made from wood with bearings that supported the main axle from the top and bottom. The entire structure was designed to be able to be disassembled, because we knew that it would be too big for us to transport otherwise.

The microcontroller was mounted to the center of the axle and spun with the globe. External power was transmitted to the spinning globe via copper machined slip rings we fitted onto the top and bottom of the axle. The axle was driven by an electric motor and speed controller. A single magnet and hall effect sensor was used to detect the globe position. The microcontroller program detected when the hall sensor was triggered in order to determine how long it took for the globe to go through a full rotation, and would subdivide that time by our desired horizontal display resolution to determine when to send updates to the LED strips.

When we debuted the Orbital Rendersphere at the World Maker Faire in NYC in 2013, it became an instant crowd favorite and was honored with 4 Editor’s Choice ribbons and 1 Educator’s Choice ribbon, and was subsequently featured as a project spotlight on BeagleBoard.org. Moreover, it was an incredible adventure working together with a diverse group of people who each brought their unique talents to bear on making an audacious dream a reality.